Technology Overview

Main Menu

Technology Overview

As an eco-friendly activated carbon regeneration technology using superheated steam for water treatment and atmospheric fields, it makes efficient use of environmental resources and make them sustainable.

As an eco-friendly activated carbon regeneration technology using superheated steam for water treatment and atmospheric fields, it makes efficient use of environmental resources and make them sustainable.

What is Superheated Steam?

If the water present in the steam is completely vaporized, the water vapor becomes dry water vapor (dry saturated steam) in gaseous state over 100℃, and it is heated to be in a state beyond the saturation temperature, called Superheated Steam.

If the water present in the steam is completely vaporized, the water vapor becomes dry water vapor

(dry saturated steam) in gaseous state over 100℃, and it is heated to be in a state beyond

the saturation temperature, called Superheated Steam.

(dry saturated steam) in gaseous state over 100℃, and it is heated to be in a state beyond

the saturation temperature, called Superheated Steam.

If the water present in the steam is completely vaporized, the water vapor becomes dry water vapor (dry saturated steam) in gaseous state over 100℃, and it is heated to be in a state beyond the saturation temperature, called Superheated Steam.

Required amount at creation

Superheated steam is a heat medium containing

more heat than heated air PROCESS

more heat than heated air PROCESS

Superheated steam is a heat medium containing

more heat than heated air PROCESS

| Temperature | Superheated steam | Heated Air |

| 200℃ | 2,780kJ / kg | 208kJ / kg |

| 300℃ | 2,980kJ / kg | 312kJ / kg |

Process

Step 01

Saturated steam

(Wet steam)

(Wet steam)

Water vapor in

gas-droplet mixture

gas-droplet mixture

Step 02

Heating

Completely vaporizing

the water present in

water vapor (wet steam)

the water present in

water vapor (wet steam)

Step 03

Superheated steam

(Dry steam)

(Dry steam)

Heated steam above

saturation temperature

saturation temperature

Characteristics of superheated steam

Characteristics of superheated steam

Its heat capacity is very compared to heated air

Rapid heating of the heated object(activated carbon), shortening the heating time

Rapid heating of the heated object(activated carbon), shortening the heating time

• Transfer speed increases in accordance with temperature at the same pressure

• Specific heat under constant pressure about twice as large as heating air → Excellent heating capacity

• Very high enthalpy due to latent heat → High energy

• Specific heat under constant pressure about twice as large as heating air → Excellent heating capacity

• Very high enthalpy due to latent heat → High energy

- Superheated steam

- Heated Air

Energy efficient superheated steam

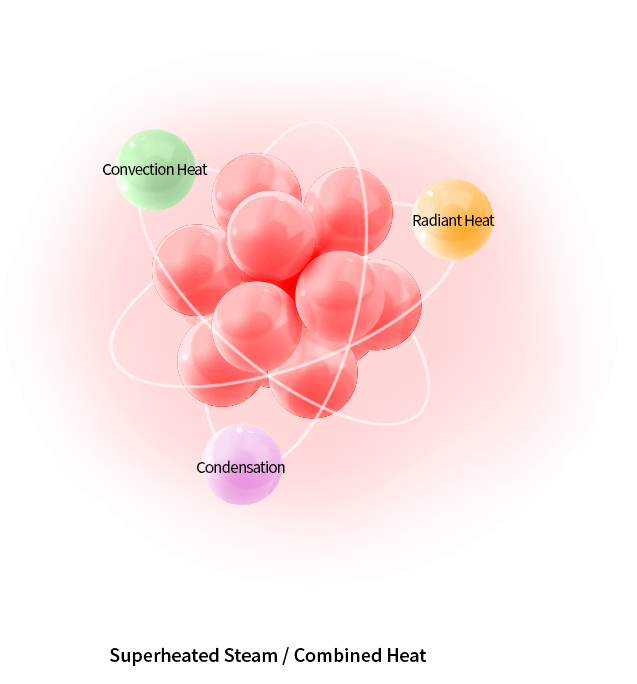

Heat transfer by air is limited to convection heat transfer. Superheated steam, on the other hand, has excellent thermal efficiency due to the complex heat transfer action transmitted by convection heat, radiant heat and condensation.

Heat transfer by air is limited to convection heat transfer. Superheated steam,

on the other hand, has excellent thermal efficiency due to the complex heat

transfer action transmitted by convection heat, radiant heat and condensation.

on the other hand, has excellent thermal efficiency due to the complex heat

transfer action transmitted by convection heat, radiant heat and condensation.

Heat transfer by air is limited to convection heat transfer. Superheated steam, on the other hand, has excellent thermal efficiency due to the complex heat transfer action transmitted by convection heat, radiant heat and condensation.

Safe equipment without risk of fire

The superheated steam regeneration method can suppress oxidation and combustion of the heated object by heat treatment in an oxygen-free state

(oxygen deficiency among the three elements of combustion).

(oxygen deficiency among the three elements of combustion).

The superheated steam regeneration method can suppress oxidation and

combustion of the heated object by heat treatment in an oxygen-free state

(oxygen deficiency among the three elements of combustion).

combustion of the heated object by heat treatment in an oxygen-free state

(oxygen deficiency among the three elements of combustion).

The superheated steam regeneration method can suppress oxidation and combustion of the heated object by heat treatment in an oxygen-free state (oxygen deficiency among the three elements of combustion).

Superheated Steam Activated

Carbon Regeneration

Carbon Regeneration

The inside of the regeneration tower and the activated carbon become high

temperature due to superheated steam injected from the irradiation tube

[Desorption and Pyrolysis of Organics by Continuous Superheated Steam Injection]

temperature due to superheated steam injected from the irradiation tube

[Desorption and Pyrolysis of Organics by Continuous Superheated Steam Injection]

The inside of the regeneration tower and the activated carbon become high temperature due to superheated steam injected from the irradiation tube

[Desorption and Pyrolysis of Organics by Continuous Superheated Steam Injection]

[Desorption and Pyrolysis of Organics by Continuous Superheated Steam Injection]

───── Examicer

─── Superheated steam inflow

──── Recycling tower

── Activated carbon

─── Injectiong of superheated steam

──── Pore particles of

activated carbon

activated carbon

Examicer

Superheated steam inflow

Recycling tower

Activated carbon

Injection of super heated steam

Pore particles of activated carbon

Before recycling

After recycling

① Injection

② Drying

③ Activation

Recycling process according to temperature change of activated carbon after superheated steam input

Recycling process according to temperature change of activated carbon after superheated steam input

100~200˚C

Thermal dry for water separation

250˚C

Decomposition of H2S compounds separating deoxidation, desulfurization, combined moisture CO2

Decomposition of H2S

compounds separating

deoxidation, desulfurization,

combined moisture CO2

compounds separating

deoxidation, desulfurization,

combined moisture CO2

Decomposition of

H2S compounds separating deoxidation, desulfurization, combined moisture CO2

H2S compounds separating deoxidation, desulfurization, combined moisture CO2

340˚C

Decomposition of fat-

containing substances

(Decomposition into low molecular aliphatic substances such as methane)

Decomposition of fat-containing

substances (Decomposition into

low molecular aliphatic substances

such as methane)

substances (Decomposition into

low molecular aliphatic substances

such as methane)

Decomposition of fat-containing

substances (Decomposition into

low molecular aliphatic substances

such as methane)

380˚C

Decomposition of C-containing dry matter

Decomposition of

C-containing dry matter

C-containing dry matter

400˚C

Decomposition of C-0, C-N binders

500~700˚C

Carbide formation

Carbide formation

Water treatment biz.

Project that designs, manufactures and construct activated carbon automatic recycling filtration, including a device that removes specific pollutants in water by using activated carbon and regenerates activated carbon destroyed by superheated steam

Project that designs, manufactures and construct activated

carbon automatic recycling filtration, including a device that

removes specific pollutants in water by using activated carbon

and regenerates activated carbon destroyed by superheated steam

carbon automatic recycling filtration, including a device that

removes specific pollutants in water by using activated carbon

and regenerates activated carbon destroyed by superheated steam

Project that designs, manufactures and construct activated carbon automatic recycling filtration, including a device that removes specific pollutants in water by using activated carbon and regenerates activated carbon destroyed by superheated steam

Atmospheric treatment

Project that designs, manufactures and construct activated carbon automatic recycling tower, including a device that adsorbs and removes odor-causing substances such as VOCs from the factory with activated carbon and regenerates the destroyed activated carbon using superheated steam.

Project that designs, manufactures and construct activated carbon

automatic recycling tower, including a device that adsorbs and

removes odor-causing substances such as VOCs from the factory

with activated carbon and regenerates the destroyed activated

carbon using superheated steam.

automatic recycling tower, including a device that adsorbs and

removes odor-causing substances such as VOCs from the factory

with activated carbon and regenerates the destroyed activated

carbon using superheated steam.

Project that designs, manufactures and construct activated carbon automatic recycling tower, including a device that adsorbs and removes odor-causing substances such as VOCs from the factory with activated carbon and regenerates the destroyed activated carbon using superheated steam.